The world’s first all-electric passenger airplane looks like it could be at home in the sea. Instead of a traditional metal tube, its fuselage resembles an orca — with a sharp nose and a wide body that tapers dramatically to a T-shaped fin at the rear. Its wings are long, knifelike. The plane’s twin propellers, driven by quiet, piston-free motors, thrum like the future.

Known as Alice, this airplane is the invention of Seattle-area startup Eviation. It is built to carry nine passengers as far as 500 miles on a charge — a range that could connect San Francisco to San Diego, or Boston to Washington, D.C. — with what once seemed like a pipe dream: carbon-free flight.

Alice represents one of the boldest solutions to one of the most difficult obstacles to a zero-emission future. Airplanes produce about 2.4 percent of annual greenhouse pollution — or the equivalent of four New York Cities. Unchecked, aviation emissions could soon hog up to one-sixth of the world’s remaining “carbon budget,” or the amount of CO2 humans can still release without producing catastrophic warming. Yet the industry has lagged behind other modes of transport in pivoting from fossil fuels, in large part because green alternatives have been too heavy to get off the ground.

When I visited Eviation headquarters in January, the Alice prototype was conducting high-speed runway testing in advance of its highly anticipated maiden flight. The aircraft is the brainchild of Israeli entrepreneur Omer Bar-Yohay, a lanky 43-year-old veteran of the electric-car-battery industry who co-founded Eviation in 2015.

To most observers back then, the physics of electric flight seemed, well, fucked: Heavy batteries didn’t pack enough power to propel an aircraft a meaningful distance. But as Bar-Yohay began probing the problem, he realized the limiting factor wasn’t the power packs. It was legacy airplanes. “The prevailing thinking,” Bar-Yohay told me on the tarmac, “was that someone was going to convert a plane,” much as Elon Musk had repurposed the chassis of a Lotus Elise to fashion the first Tesla roadster. But the range of such a conversion — 150 miles or so — screamed novelty, not profit.

Bar-Yohay is a scientist by training, and his breakthrough came when he calculated that building an electric airplane from scratch — with lightweight composite materials, super-efficient electric motors, fly-by-wire systems — could shave off enough weight to extend the range to 400 miles or more. “If you built a very, very slick aircraft,” he says, “there was a mission profile that worked.”

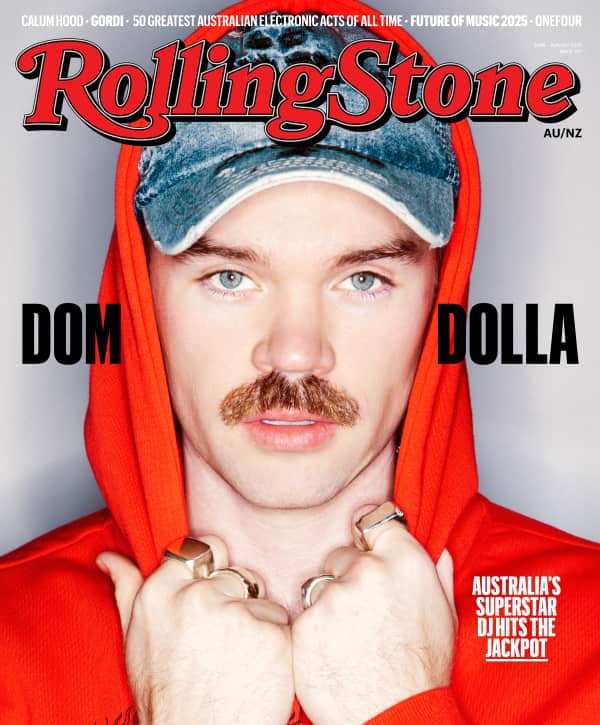

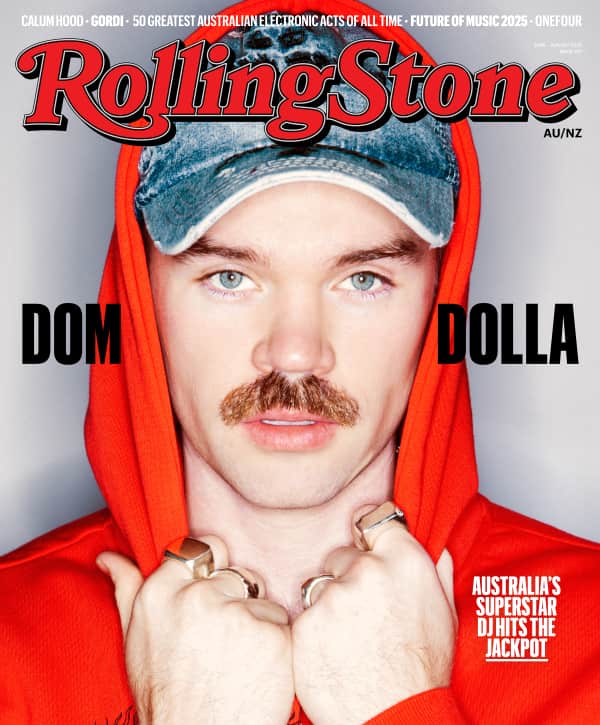

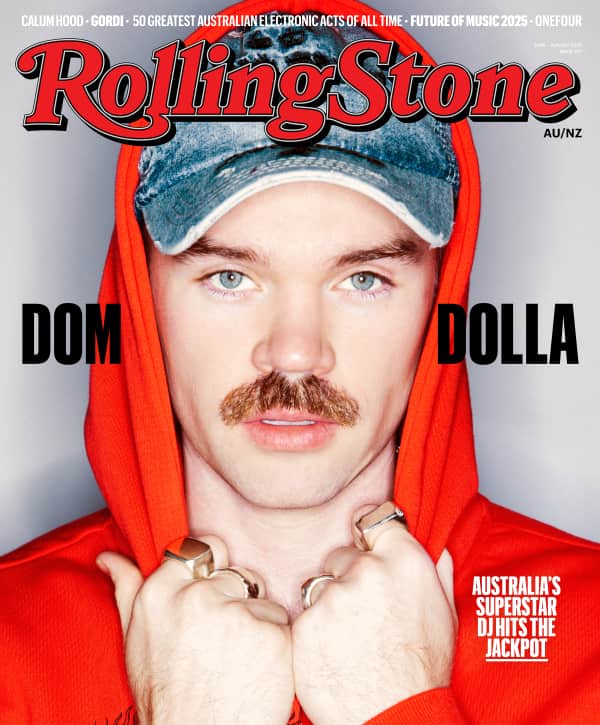

Love Music?

Get your daily dose of everything happening in Australian/New Zealand music and globally.

He lays out the business case for Alice in an aviation system where long-haul journeys are completed with short connecting flights. “In 2019, the world sold 4.5 billion air tickets,” he says. “More than half were under 350 miles. There’s a huge market.”

Electric aviation is in its infancy, and the record book won’t wow fans of The Right Stuff. The fastest all-electric flight — by a Rolls-Royce single-seater — set a record of 345 mph in January, going less than half the speed of sound. The longest flight by an electric-powered aircraft to date, a modified Cessna, is a mere 341 miles.

The limitations of electric flight might seem to outweigh the opportunities. But aviation’s contribution to global warming is more significant than commonly understood. “Flying is by far the worst thing we do for the environment,” says Jeff Engler, CEO of the aviation startup Wright Electric. He points to research that the emissions linked to a single seat aboard a round-trip trans-Atlantic flight can wipe out the carbon benefits of eating vegetarian for a decade.

Worse: Airplanes also leave behind short-lived contrails and cirrus formations that trap additional heat in the atmosphere. According to a November study in Environmental Research Letters, aviation’s “warming footprint” — its true contribution to climate change — has become “at least twice as large as its carbon footprint.”

But flying without fossil fuel is devilishly difficult. Not only does conventional fuel deliver about 50 times more power per pound than a battery, but the weight of the fuel load decreases the longer a plane travels, while battery packs just become dead weight after they’ve expended their electrons.

This means there are practical limits to what pure, battery-powered aviation can accomplish — even with hoped-for advances in technology. Other innovators hope to produce electricity on board instead, using fuels like hydrogen. Wright Electric is an Albany, New York-based startup with backing from the U.S. military and NASA. It has developed an ultra-light, ultrapowerful, two-megawatt motor capable of operating at 40,000 feet. Engler bills it as an “electric jet engine,” and Wright Electric has announced plans to swap the motors into an existing 100-passenger short-haul jet from Europe.

There are critical details to sort out — including whether the plane would be powered by hydrogen fuel cells or another green power source. But by 2026, Wright hopes to debut an aircraft that can compete on commuter routes like Paris-to-London or Los Angeles-to-San Francisco. “The busiest routes in the world are one-hour flights,” Engler says, adding that he hopes to take a bite out of the CO2 emissions from that market first, “and, then, over time, expand the range.”

It’s one thing to listen to a founder dream big about deploying electric airplanes. It’s another to see that dream hurtle down a runway. Eviation is headquartered at a municipal airfield in Arlington, Washington. The location is close enough to Seattle to tap into engineering talent from local aerospace behemoth Boeing, but far enough from SeaTac not to have to wrangle for airspace.

The FAA requires reams of data before a new aircraft leaves the ground, and when I visited, Bar-Yohay was putting Alice through its paces, accelerating to speeds just short of those required for flight. Eviation expects to complete runway tests this winter and anticipates Alice’s first flight this spring. The company will then build three sister aircraft to complete close to 2,000 hours of flight time before the plane is fully certified.

Getting Alice to this moment has been a trial by fire, all too literally. Eviation’s first prototype debuted to rave reviews at the Paris Air Show in 2019, but in early 2020, a fire in the lithium-ion battery pack destroyed that aircraft. The lesson was as valuable as it was painful. The Eviation team redesigned the power system to ensure that a single failed battery cell can’t spark a packwide failure, and the plane can complete a safe, powered landing. (Consumer comfort with battery safety poses an ongoing challenge; a Nature review warns starkly, “It is difficult to overemphasize current concerns with lithium batteries on commercial aircraft.”)

Building, and rebuilding, Alice gave the Eviation team freedom to innovate. Its battery packs weigh more than 8,000 pounds and are hidden in chubby, curved sections on either side of the fuselage. The packs are strong enough to contribute to the integrity of the aircraft, saving weight. And the wide bottom of the plane acts like a wing. “The body itself takes part in lifting the weight of the battery,” Bar-Yohay says.

The name of Eviation’s modern aircraft is a throwback — both to Lewis Carroll and 1960s psychedelic rock. “After a very long working day and night, we were listening to Jefferson Airplane’s ‘White Rabbit,’” Bar-Yohay explains. “Someone said, ‘Hey, let’s just call it Alice.’ And it stuck.”

The plane’s technical specs are eye-popping — it charges six times as fast as the fastest Tesla, needing a half hour of charge time for an hour of flight. Eviation insists the business case for the plane is as strong as the environmental one. Alice has durable motors, fewer moving parts, and digital electrical systems. It requires little maintenance, aside from scheduled battery replacement that can be done at a fraction of the price of a carbon-powered plane’s upkeep. “We can cut between 50 and 70 percent of the [operating] cost for an equivalent jet,” Bar-Yohay insists.

At launch, Alice will have three models — an executive plane, a commercial nine-seater, and a cargo craft. Shipping giant DHL has already ordered 12. As part of the company’s transition from a startup to manufacturer, founder Bar-Yohay stepped down as CEO recently, but remains on the board.

Eviation expects to deliver its first planes in 2024. Until then, the image of Alice speeding down the runway — propellers cutting the air without the clack of combustion — stands as a metaphor for the promise of electric aviation: tantalizingly close to takeoff.

From Rolling Stone US